Plastic product manufacturing involves creating items from plastic materials, such as food containers, kitchenware, and automotive parts. The industry is vital to our everyday lives, providing affordable and sustainable solutions in everything from packaging to medical devices. This article aims to guide potential entrepreneurs on how to start a successful plastic products manufacturing business.

1. Market Analysis

The plastic products market includes a wide range of items, from containers and toys to automotive parts. As consumers look for convenience and durability, the demand for these products continues to rise.

1.1. Overview of Global Plastic Market Growth

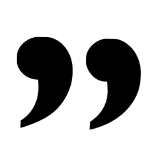

The global plastic market was worth $599 billion in 2022. It is expected to grow from $624.16 billion in 2023 to $867.43 billion by 2031, at an average annual growth rate of 4.2% during the 2024-2031 period (According to SkyQuest)

This growth is driven by factors such as developing infrastructure, urbanization, and the rise of small businesses.

1.2. Key Niches to Consider

When starting a plastic products manufacturing business, it’s essential to identify the key niches that offer the most potential for success. Some of the most promising niches include:

- Consumer Products

The consumer products segment is a vast and lucrative market for plastic products. This includes items such as household goods, toys, and packaging materials. These products are in high demand due to their versatility, durability, and cost-effectiveness.

- Industrial Applications

The industrial sector also presents significant opportunities for plastic products manufacturers. Plastic components are widely used in automotive, construction, and manufacturing industries, among others. These industrial applications require specialized plastic products that meet specific performance and safety standards.

1.3. Identifying Target Customers

Defining your target customers is a crucial step in the success of your plastic products manufacturing business. By understanding the needs, preferences, and pain points of your potential customers, you can tailor your products and marketing strategies to effectively reach and serve them.

- Some key factors to consider when identifying your target customers include:

- Demographic data (age, location, income, etc.)

- Psychographic data (interests, values, lifestyle preferences, etc.)

- Industry-specific needs and requirements

- Competitor analysis to identify underserved market segments

2. Business Plan Development

Having a solid business plan is super important if you want your plastic products manufacturing business to succeed.

The business plan is like a roadmap – it lays out your company’s goals, strategies, and financial projections. It helps you stay focused and on track with what you’re trying to achieve, and banks or investors usually want to see one if you’re looking for funding.

Get this – companies with a business plan actually grow 30% faster than those that don’t plan things out. So having a killer business plan can really pay off in a bunch of ways:

- It forces you to do your homework on the market, check out the competition, and figure out exactly who your target customers are. This market analysis helps you understand the demand for your products and how to make your business stand out.

- The business plan also lets you develop a detailed marketing strategy to reach and attract customers. This includes plans for pricing, getting your products out there, and promoting your business.

- The financial projections in the business plan show that your business model is legit and that you can actually make some money. Investors are gonna want to see realistic financial forecasts before they hand over any cash.

- The business plan can also act as a backup plan, helping you anticipate and prepare for any challenges or changes in the market. This flexibility is super important for keeping your business going strong in the long run.

Additionally, before moving forward, create a SWOT analysis to evaluate your strengths, weaknesses, challenges, and opportunities in entering this market. This will give you a broader perspective on what you will face as you dive into the plastic manufacturing industry.

3. Equipment and Technology

You are a factory, you cannot operate without machines and equipment, so what will you need?

3.1. Essential Machinery Needed

When it comes to the essential machinery for injection molding and extrusion, the two key pieces of equipment are:

- Injection Molding Machines: These machines are the heart of the injection molding process. The cost of an injection molding machine can range anywhere from $50,000 for a small, used machine up to $500,000 or more for a large, high-end model.

The size and capabilities of the machine you need will depend on the specific parts you’re producing – bigger and more complex parts require more powerful, expensive machines.

- Extruders: Extruders are the workhorse of the extrusion process, melting and pushing plastic material through a die to create continuous products like sheets, pipes, and profiles. Extruder costs can range from $30,000 for a small, single-screw model up to $500,000 or even millions for a large, twin-screw industrial extruder.

Again, the size and features you need will depend on your specific extrusion applications.

3.2. Costs and Budgeting for Equipment

When budgeting for injection molding and extrusion equipment, there are a few key factors to consider beyond just the machine cost:

- Mold/die costs: High-quality molds and dies can easily cost $10,000 to $100,000 or more, depending on their complexity.

- Installation and setup: You’ll need to budget for things like rigging, electrical work, and training, which can add 10-20% to the equipment cost.

- Maintenance and repairs: Expect to spend 5-10% of the machine’s value per year on maintenance and potential repairs.

So for example, if you’re looking to buy a $300,000 injection molding machine, you should budget:

- An additional $30,000 to $60,000 for the mold

- $30,000 to $60,000 for installation and setup

- $15,000 to $30,000 per year for maintenance

That brings the total 1st year cost to around $375,000 to $450,000.

3.3. Importance of Technology Adoption

Staying up-to-date with the latest injection molding and extrusion technology is crucial for remaining competitive. Newer, more advanced machines can offer benefits like:

- Higher energy efficiency, reducing operating costs by 20-30%

- Faster cycle times, boosting production output by 10-15%

- Improved part quality and precision, reducing scrap and rework

- Greater flexibility to handle a wider range of materials and part designs

Investing in the right equipment and technology can give you a major advantage over competitors still using older, less efficient machinery. It’s an investment that can pay off big in the long run.

4. Legal and Regulatory Considerations

Legal and regulations are the things you must definitely comply with when running a plastic products manufacturing business to be allowed to do business and gain trust from stakeholders.

4.1. Safety First

When you’re running a factory, safety has to be your top priority. There are all kinds of standards and regulations you need to follow to protect your workers – things like machine guarding, personal protective equipment, and emergency planning. Ignore this stuff at your own risk, because nobody wants to deal with workplace accidents or OSHA fines.

4.2. Licenses and Permits

Before you even think about firing up that factory, you gotta make sure you’ve got all the right paperwork in order. Depending on your industry and location, you might need permits for things like air emissions, water discharges, hazardous waste handling, and more. It’s a real jungle out there, so do your research and make sure you’re covered.

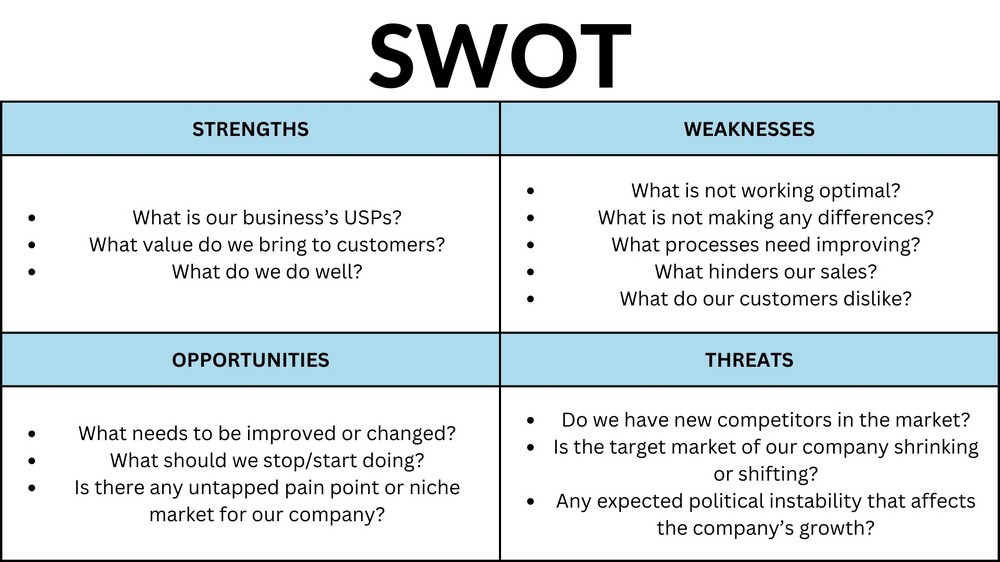

To be certified and exported to the international market, factory owners will need to meet certifications such as RoHS (Restriction of Hazardous Substances) and FDA (U.S. Food and Drug Administration).

- Compliance with RoHS is mandatory for many types of EEE (Electrical and Electronic Equipment) products, including consumer electronics, household appliances, industrial equipment, medical devices, etc. RoHS is mandatory when exporting to the European Union (EU) market.

- The FDA certification, on the other hand, focuses on the U.S. market and regulates the safety, efficacy, and quality of a wide range of products, including food, drugs, medical devices, cosmetics, and more.

4.3. Environmental Regulations

Plastic products manufacturing business can be tough on the environment, many localities also have a bad mentality when it comes to plastic, so the government’s got a bunch of rules to keep things clean and green.

You’ll need to stay on top of regulations around air pollution, water pollution, waste disposal, and even endangered species. Trust me, you don’t want the EPA knocking on your door!

5. Supply Chain Management

Of course, this is almost the most important step. You may have an idea for a unique product, but if you don’t optimize your inputs and ensure you have outputs, you won’t be able to sell anything.

5.1. Sourcing Raw Materials

When it comes to sourcing raw materials, you gotta be on your A-game. You need to find suppliers that can deliver the goods – literally!

Look for vendors that can provide high-quality materials at a fair price and get them to you on time, every time. Building those solid supplier relationships is key. You don’t want any hiccups in your supply chain, you know?

5.2. Establishing Supplier Relationships

Building strong relationships with your suppliers is crucial. You want partners you can trust, who have your back and are just as invested in your success as you are. Get to know them, understand their capabilities and limitations, and work together to overcome any challenges that pop up.

Open communication is a must – no surprises allowed! The more you can align on goals and processes, the smoother your plastic products manufacturing business will run.

5.3. Distribution Channels for Finished Products

Once you’ve got your raw materials sorted and your products are ready to go, you need to figure out the best way to get them into the hands of your customers. This could mean working with wholesalers, retailers, or even shipping directly.

Do your research, crunch the numbers, and choose the distribution channels that make the most sense for your business. You want to make sure your products are reaching the right people, at the right time, without breaking the bank on logistics. It’s all about finding that sweet spot between cost and convenience.

6. Marketing and Sales Strategies

To make your plastic products shine, start with a strong brand. Create a catchy name and eye-catching logo that truly reflects what you offer. It’s fun and will help you stand out in a crowded market!

Think about how you’ll reach your customers. A combination of online and offline marketing can work wonders. Use social media platforms to showcase your products, run targeted ads, and engage your target audience. However, don’t underestimate the power of face-to-face connections, if you get the chance, take your customers on a factory tour.

Finally, focus on building a solid customer base and network. Engage your target audience by responding to comments and messages on social media. Attend trade shows to meet industry insiders and potential customers in person. Providing great service and high quality products will keep customers coming back, and happy customers will often spread the word, helping your business grow even more!

However, running a plastic products manufacturing business can be challenging, costly, and demanding, and not every country is suitable for establishing a factory due to high labor and land costs, as well as concerns about the availability of raw materials.

If you reconsider and decide against manufacturing, a better option might be to become a distributor or open a physical retail store, allowing you to source products directly from factories, which can be more cost-effective and efficient.

| Here are the steps and experiences that Inochi has distilled and implemented to achieve rapid success and growth. Of course, there are still other industry secrets of manufacturing plastics that will take time and experience to understand.

Inochi has grown to the point where we have optimized our production process, allowing distributors to import high-end plastic household products at competitive prices. So, think of Inochi Global when you need a source for goods. If you need more information about our products, feel free to contact us on WhatsApp: +84 83 214 8855. |

In conclusion, starting a plastic products manufacturing business involves quite a number of complex steps and requires a detailed implementation plan. With dedication and the right approach, aspiring entrepreneurs can achieve great success in this growing industry.